Einfacher Rollschirm

Application area: Tensioning device for wire ropes in roll screen systems, especially for tight installation spaces Material: High-quality steel, Sendzimir galvanized for optimal corrosion protection Installation: Secured exclusively with M6 screws for safe and stable fixation Special feature: Compact design allows space-saving installation Advantages: Enhanced wire tension stability Durable construction thanks to galvanized steel Ideal for roll screen systems in greenhouses Prevents unwanted slack in the wire The Compact wire tensioner for roll screen is specifically designed for tight installation spaces in shading systems. Its compact design enables stable wire tension and ensures reliable fastening. Made from Sendzimir galvanized steel, the component offers optimal corrosion protection. Installation is carried out exclusively with M6 screws, ensuring particularly secure fixation. This makes the tensioner ideal for use in greenhouses where precise and long-lasting wire tension is required. The construction prevents unwanted slack and maintains consistent tension over extended periods. Users also benefit from increased overall wire guidance stability, making the tensioner an indispensable element in professional roll screen systems.

Application: Connecting push-pull tubes Ø 27 and Ø 32 mm in greenhouse systems Dimensions: M6 × 30 mm Material: Galvanized steel Features: Bolt head and nut sit flush with the tube to avoid collision with roller housings Packaging unit: 100 pieces The Bolts M6×30 with nuts for steel tube 27.32 are designed for connecting 27 mm and 32 mm push-pull tubes in greenhouse shading and ventilation systems. The flush fit prevents interference with diabolo roller housings.

Application: Protects and guides cables in roll-up screen systems Segment length: 204 mm Size: 10×16 mm Material: Plastic Features: Easy to assemble/disassemble even with cable inserted Packaging unit: 100 segments The Cable track 10×16 – 204 mm is designed to protect and guide cables in greenhouse roll-up systems. It enables smooth, controlled unrolling and can be easily assembled or disassembled without removing the cable. Delivered in 100-piece packs.

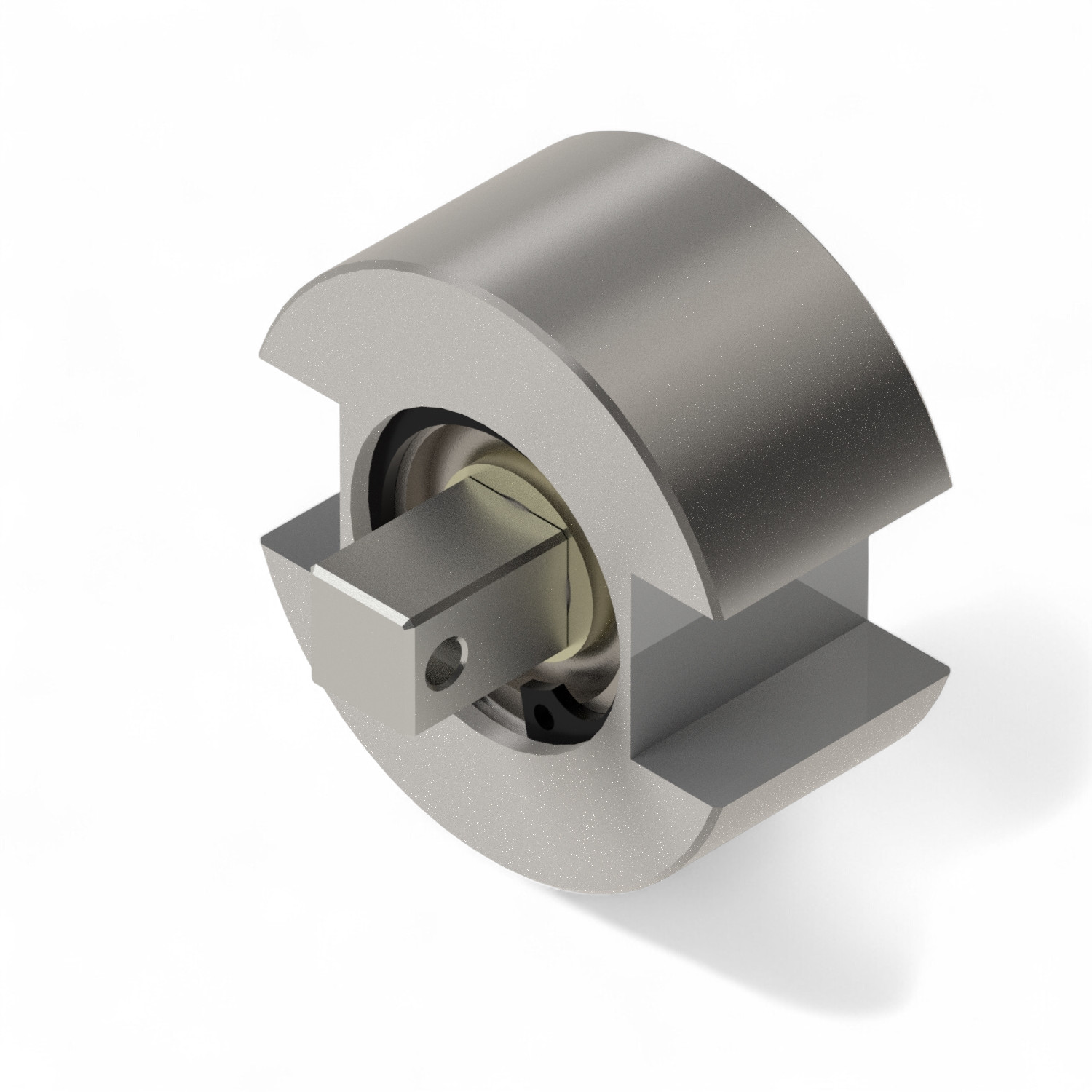

Application: Standard motor guide for RB40, RB50, and FRM50 tube motors Material: Galvanized steel Mounting: Accepts 10×10 mm square pin - includes mounting bracket Function: Moves the motor along the guide rail Packaging unit: 50 pieces The Guiding unit for tube motor RB40 / RB50 / TGU is a robust and reliable solution for guiding tube motors in greenhouse systems. It ensures smooth movement along the guide rail and is compatible with 10 mm square motor pins.

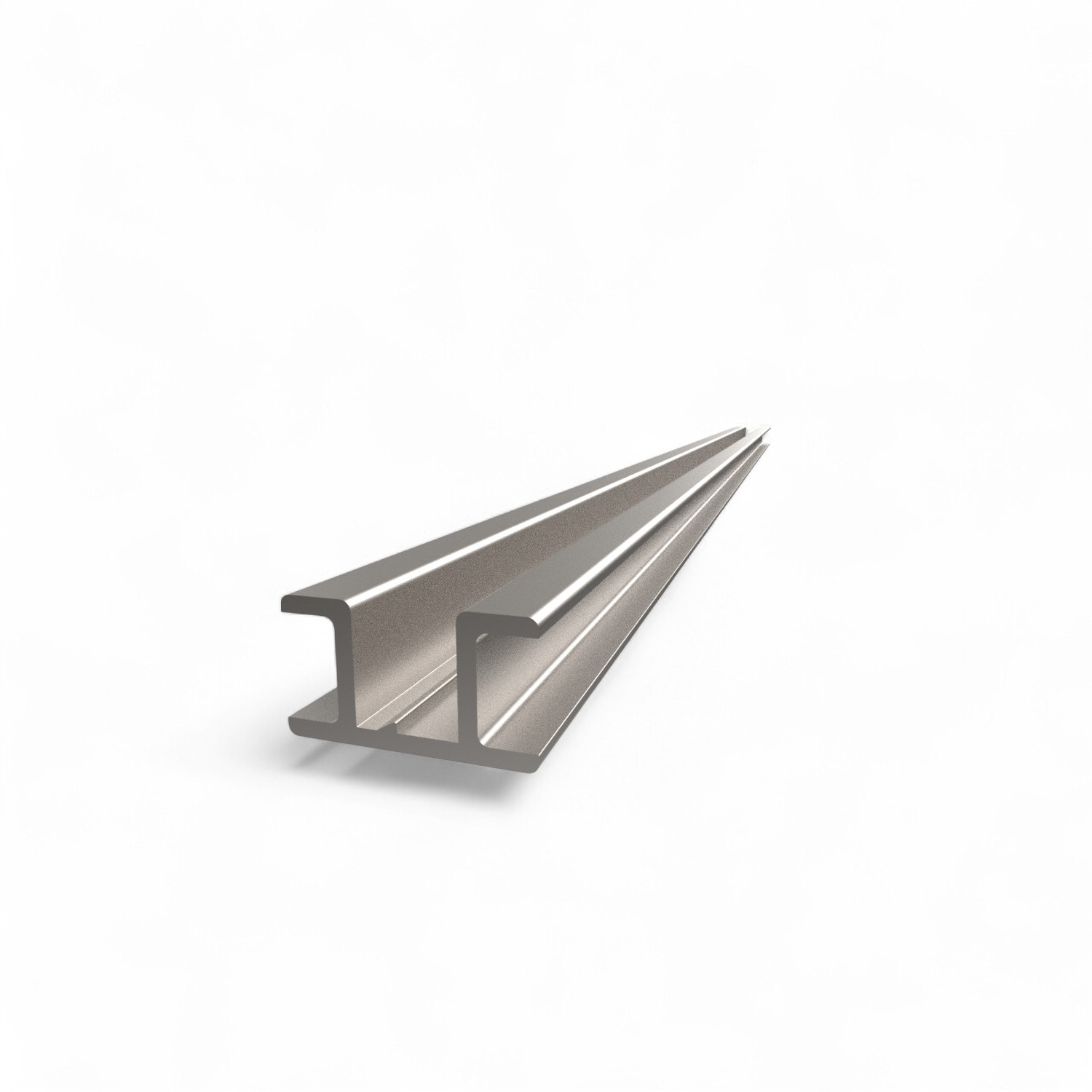

Application: Ensures straight vertical guidance of tubular motors in roll-up systems Length: 7000 mm Material: High-strength aluminum profile Compatibility: Used in combination with TGU roller carriage Mounting: For vertical installations in greenhouses The Guide rail for tube motor 7000 mm is the longest standard profile for vertical roll-up systems. It ensures smooth and accurate movement of the tube motor when paired with a roller carriage. Ideal for large-scale greenhouse installations.

Application: Horizontal shading systems in greenhouses Voltage: 230 V (120 V version also available) Torque: 50 Nm Speed: 12 rpm Mounting: Delivered with 10×10 mm square shaft adapter Tube compatibility: For 50 mm and 63 mm roll-up tubes Limit switches: Externally adjustable with Allen key The FRM50 tube motor 50-12-230 is a durable and robust drive unit for greenhouse shading systems. It offers easy installation and adjustment, and is compatible with standard motor guides and brackets.

Application: Mounting bracket for attaching energy chains to motor guides Material: Galvanized steel Mounting: Pre-punched holes for flexible installation directions Compatibility: Suitable for all standard 10×10 mm energy chains The Roll-up bracket for energy chain allows secure attachment of energy chains to the motor guide. It features pre-punched mounting holes for flexible positioning and is made of corrosion-resistant galvanized steel for long-term durability.

Application: Maintenance-free drive for roll screen systems in greenhouses and livestock buildings Material: Built into an aluminum tube with 50 mm diameter and 1.5 mm wall thickness Motor: Low-noise, single-phase, 2-pole asynchronous electric motor Limit switch: Precise electronic limit switch system with pulse counter (38 revolutions) Protection class: IP55 – high water resistance Torque: 50 Nm at 50 Hz Speed: 3.5 rpm at 50 Hz Ridder Article No.: 550032 The RB50E+ - 3.5-230/50/VK10/B50/L772 tubular motor is a powerful and maintenance-free drive unit for roll screen systems in greenhouses and livestock buildings. Thanks to its quiet operation and high water resistance, it is ideal for demanding environments. The integrated electronic limit switch system with pulse counter ensures precise control and protects the motor from overload. The IP55 protection rating allows reliable operation even in humid conditions. The motor is designed for intermittent operation and provides reliable braking performance, even under low voltage conditions.

Application: Drive shaft for greenhouse ventilation and shading systems Diameter: 1″ (≈ 33.5 mm) Wall thickness: 2.5 mm Length: 6.50 m Material: Galvanized steel Ends: Swaged for easy insertion and bolting Packaging: Bundle of 81 pieces The Steel tube Ø 1″ / 2.5 mm – 6.50 m – 81 pcs/bundle is a robust drive shaft for large greenhouse systems. Its swaged ends allow for seamless connection using bolt set 27.32. Built for high torsional loads and long-term durability.

Application: Guides roll-up tubes on the side opposite the tube motor Material: Aluminum Installation: Inserted into the roll-up tube The Endguide with Bearing for Tube Motor 50 mm is a ball-bearing guide that ensures smooth and stable movement of roll-up tubes on the side opposite the motor. It is installed directly into the tube and provides long-lasting support for shading systems.

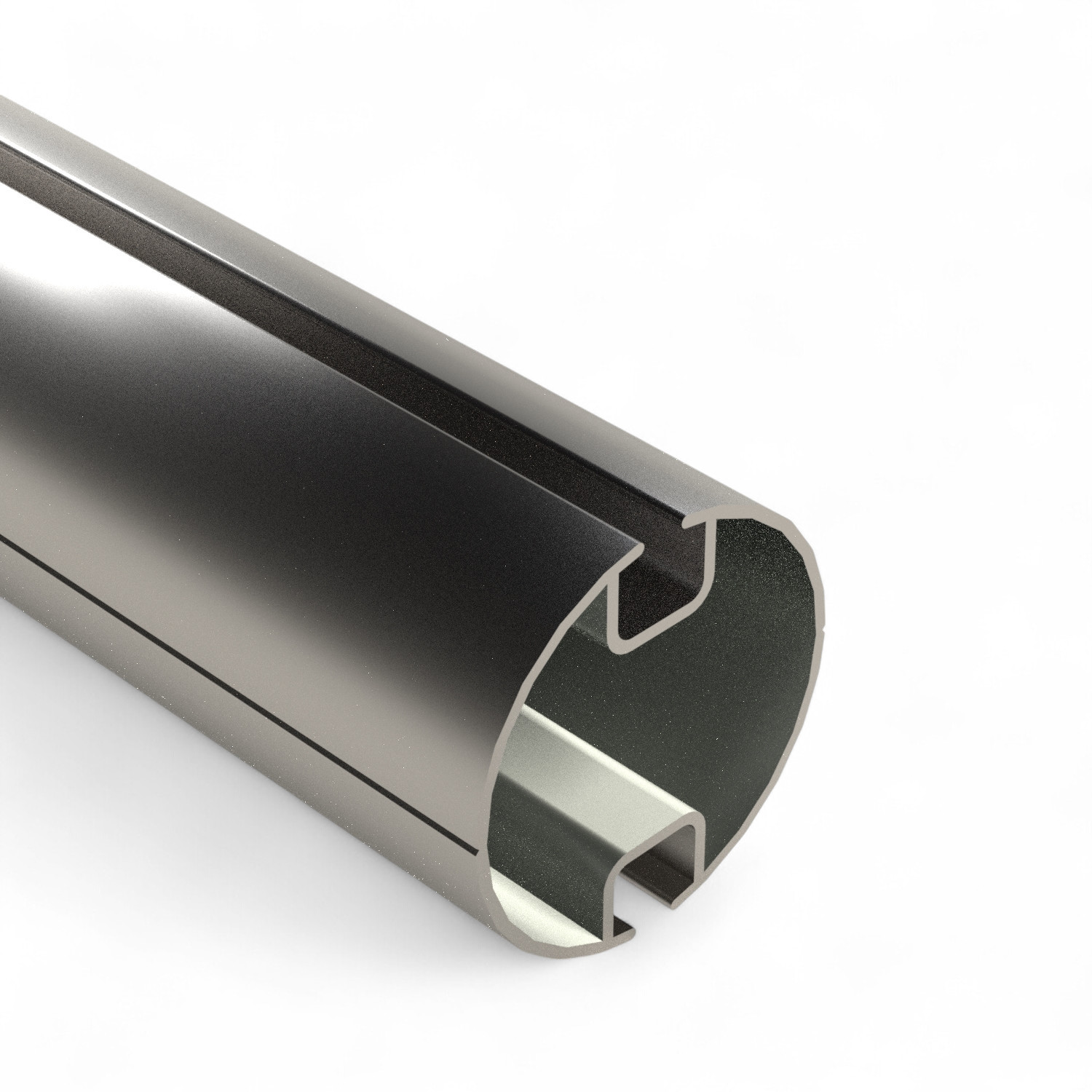

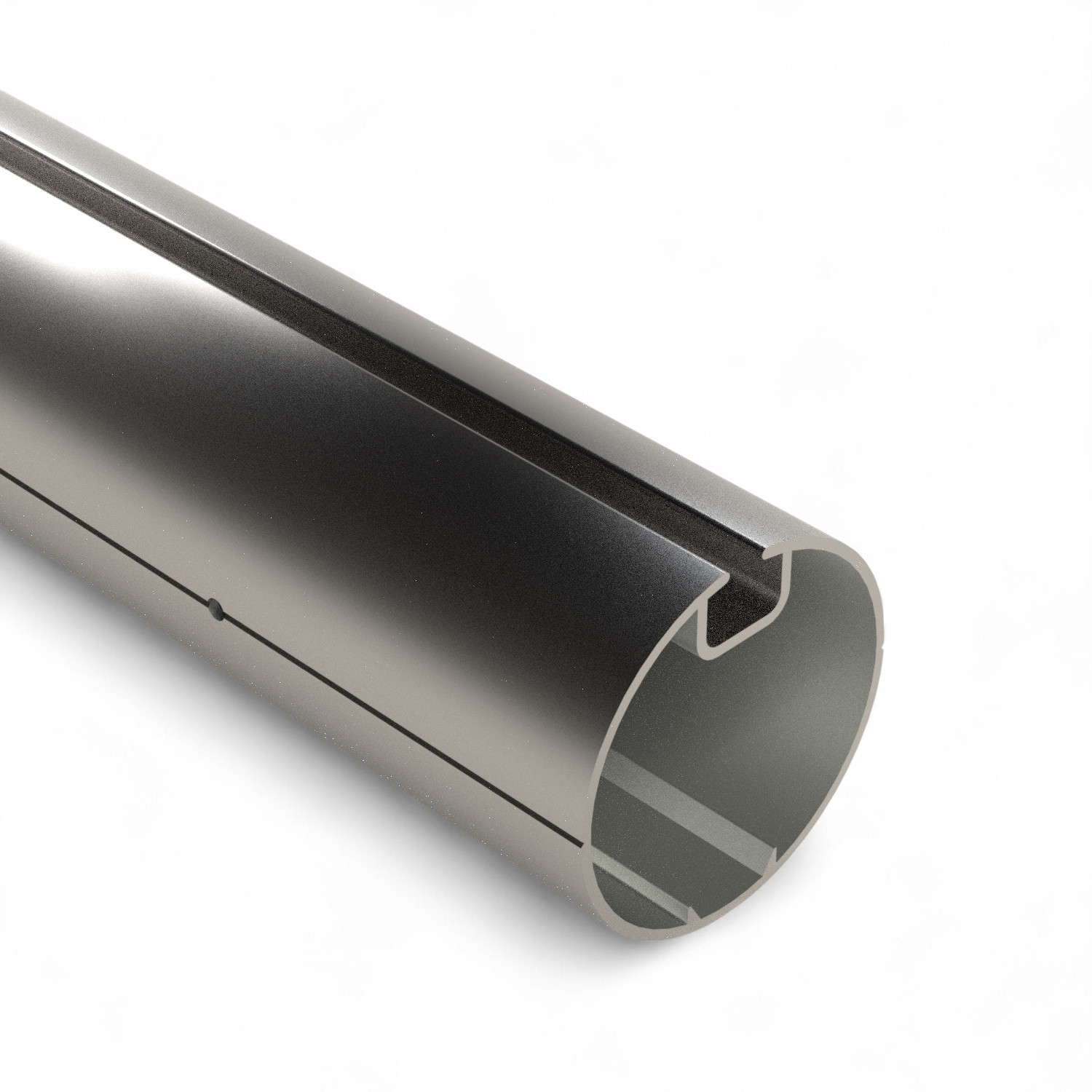

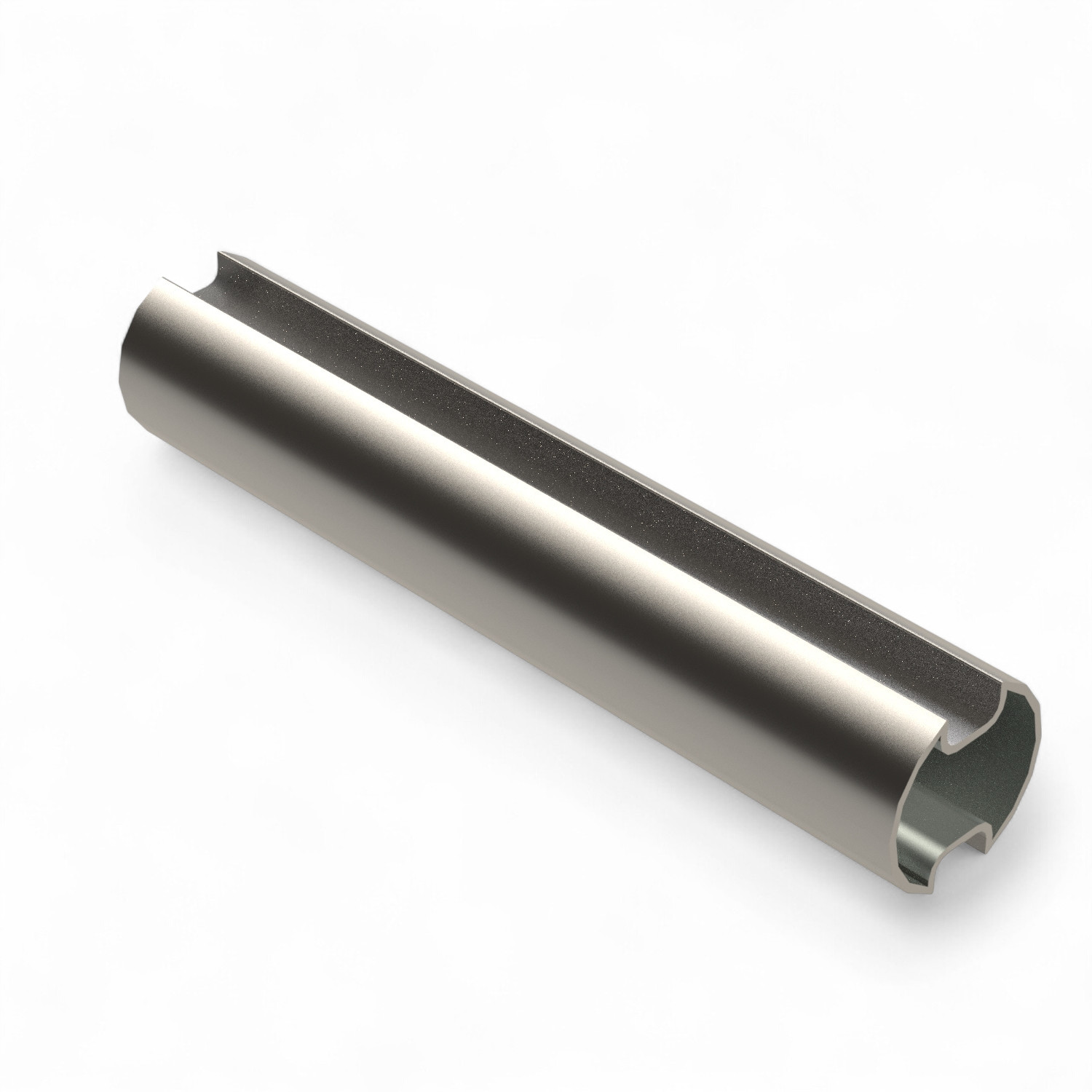

Application: Roll-up tube for twin curtain systems in greenhouses Length: 6.40 m Diameter: 50 mm (Type II) Material: Aluminum Features: Two grooves for inserting shade cloth The Aluminum tube Ø 50 mm Type II – 6.40 m is designed for twin roll-up curtain systems. It features two grooves for inserting shade cloths in opposite directions, making it ideal for counter-rolling shading solutions. Made of lightweight, corrosion-resistant aluminum.

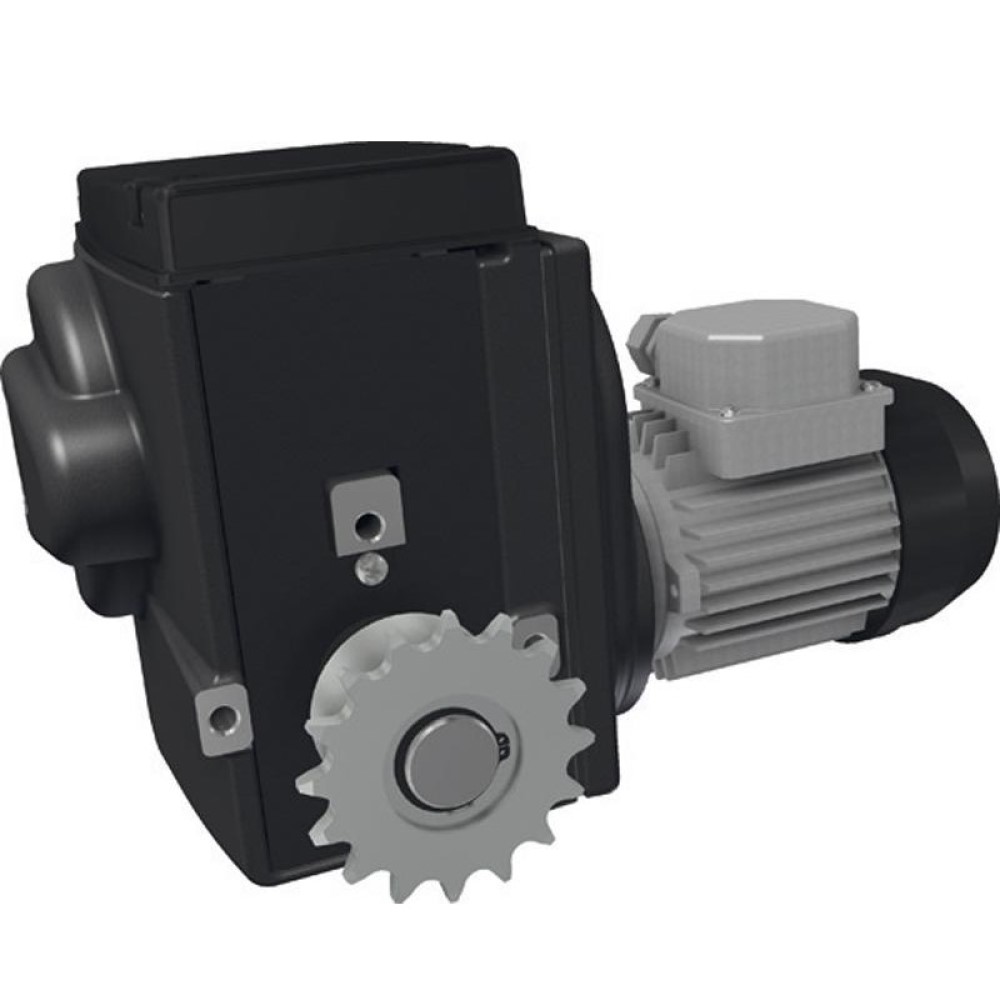

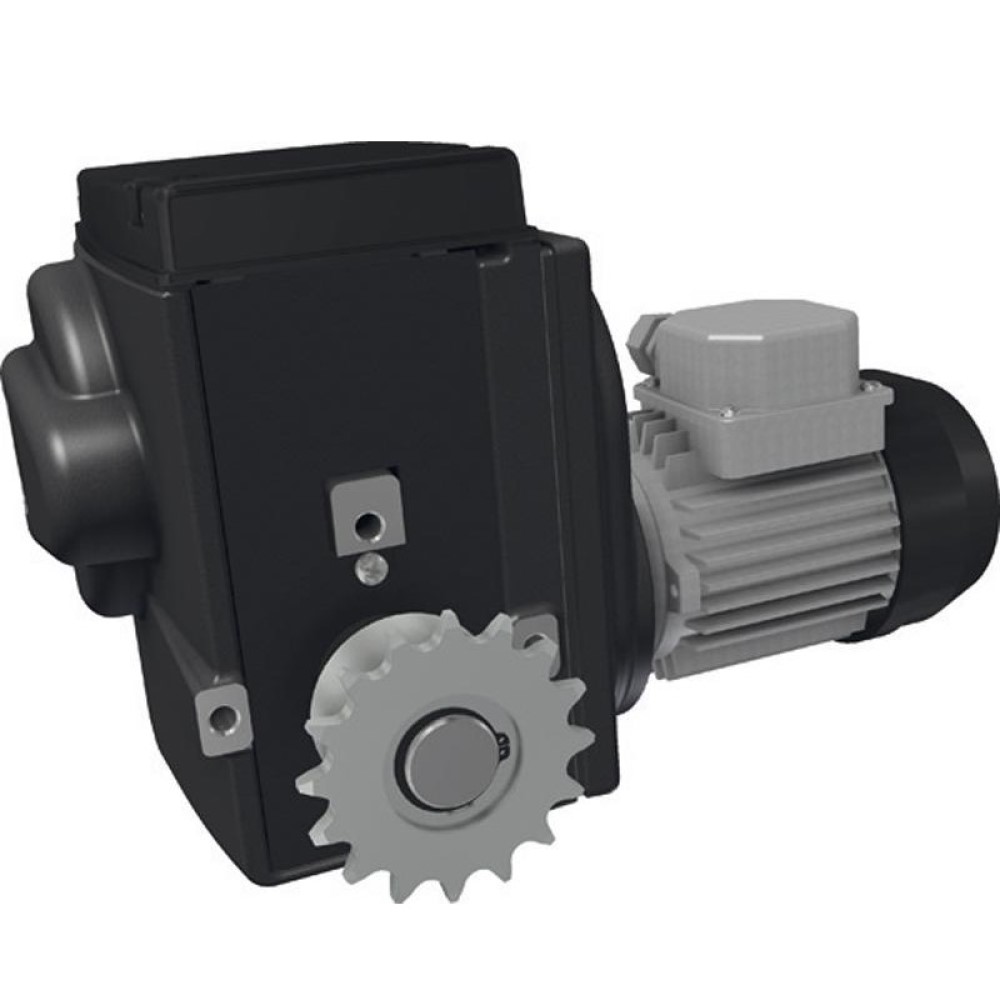

Application: For sidewall and dual roll-up screen systems in greenhouses Voltage: 230 V / 50 Hz (also available for 60 Hz) Torque: 120 Nm Speed: 11 rpm (50 Hz) / 13 rpm (60 Hz) Limit switches: Mechanical, adjustable (38 turns) Tube compatibility: For 63 mm roll-up tubes Protection class: IP44 Ridder Article No.: 550180 The RB120-11-44 tube motor is a high-torque, maintenance-free drive unit for large greenhouse shading systems. It features a sealed housing, integrated brake, and a robust planetary gearbox for long-lasting performance.

Application: For horizontal shading systems in greenhouses Voltage: 230 V, 1-phase Torque: 3.5 Nm Speed: 13 rpm Limit switches: Mechanical, adjustable Compatibility: For 50 mm drive tubes Ridder Article No.: 550025 The RB50-3.5-13 tube motor is a compact and efficient drive for greenhouse shading systems. It features mechanical limit switches and is compatible with 50 mm roll-up tubes. Ideal for small to mid-sized installations.

Application: Drive unit for ventilation and screen systems in greenhouses or barns Voltage: 400–450 V, 3~, 50 Hz Speed: 3 rpm Limit switch: Integrated linear limit switch system with a 97-turn operating range Features: Self-locking worm gear for secure shaft position at standstill Quiet operation due to optimized gear combinations Maintenance-free and compact design Optional RPU PositioningUnit or potentiometer feedback Graphite-grey powder coating Ridder Article No.: 502010 The RW 45-3 / 400–450 V is a compact and maintenance-free gear motor for greenhouse ventilation and shading systems. It features a self-locking worm gear, a precise linear limit switch system, and optional feedback integration for climate control systems.

Application: Roll-up tube for single curtain systems in greenhouses Length: 6.40 m Diameter: 50 mm (Type I) Material: Aluminum Features: One groove for inserting shade cloth Packaging: Bundle of 86 pieces The Aluminum tube Ø 50 mm Type I – 6.40 m – 86 pcs/bundle is ideal for large-scale greenhouse installations. It features a groove for inserting the shade cloth and is made of durable aluminum. Supplied in a bundle of 86 tubes.

Application: Motor guide for RB120-11/13 tube motors in vertical guide rails Material: Galvanized steel Mounting: Accepts 16×16 mm square pin - secured with cotter pin Function: Absorbs axial and rotational forces of the motor Ridder Article No.: 550505 The Guiding unit VK16 / L170 is designed for RB120 tube motors and ensures stable and precise movement within the guide rail. It is built to absorb both axial and rotational forces and is secured with a 16 mm square pin and cotter pin.

Application: Connector for 50 mm roll-up tubes (Type I & II) Length: 230 mm Material: Aluminum Mounting: Inserted into the tube and secured with aluminum rivets Packaging unit: 85 pieces The Aluminum splice for roll-up tube – 230 mm / Ø 50 mm is inserted into the roll-up tube and secured with rivets to ensure a strong, permanent connection. Compatible with both Type I and Type II 50 mm aluminum tubes used in greenhouse shading systems.

Application: Maintenance-free drive for ventilation, shading, and lifting systems in greenhouses and livestock buildings Voltage: 400–450 V, 3-phase Speed: 5 rpm Protection class: IP55 – dust and water resistant End switch: Patented linear limit switch system with high switching accuracy Temperature range: 0–60 °C Features: Quiet operation, self-locking worm gear, optional RPU PositioningUnit or potentiometer kit Ridder Article No.: 502320 The RW245-37 motor gearbox is a rugged, low-maintenance drive unit designed for greenhouse automation. Its precise limit switch system and quiet, self-locking transmission ensure reliable performance in demanding environments.

Application: For automatic or manual drive systems to open and close side ventilation Length: Adjustable from 1240 mm to 1960 mm Material: Aluminium housing with stainless steel piston rod Mounting: Quick installation via proven double-flat coupling Compatibility: Suitable for fixed-mounted motors Max. drive angle: 34° The Telescopic Shaft 1240–1960 mm is a robust and maintenance-free TransAxleUnit for lightweight greenhouse structures such as poly tunnels. Its telescopic design allows flexible adjustment and easy integration into side ventilation systems.

Application: Drive unit for ventilation, shading, and lifting systems in greenhouses or livestock buildings Voltage: 400–450 V, 3-phase Speed: 5 rpm Protection class: IP55 – sealed housing with linear limit switch system End switch: Patented linear system with operating and safety switches (adjustable up to 86 turns) Features: Self-locking worm gear, quiet operation, graphite-grey powder coating Optional: RPU PositioningUnit or potentiometer feedback kit Ridder Article No.: 502220 The RW405 motor gearbox is a compact and maintenance-free drive unit for greenhouse automation. Its precise switching system and robust construction ensure long-term reliability in demanding environments.

Application: Drive unit for ventilation, shading, and lifting systems in greenhouses or livestock buildings Voltage: 400–450 V, 3-phase Speed: 3 rpm Protection class: IP55 – sealed housing with linear limit switch system End switch: Built-in linear system with operating and safety switches (max. 86 turns) Features: Self-locking worm gear, quiet operation, graphite-grey powder coating Optional: RPU PositioningUnit or potentiometer feedback kit Ridder Article No.: 502210 The RW403 motor gearbox is a reliable and quiet drive solution for greenhouse systems. Its integrated switching system ensures precise control and long service life.

Application: Motor guide for RB120E+ tube motors in vertical guide rails Material: Galvanized steel Mounting: Accepts flat-sided shaft - secured with motor collar Function: Absorbs axial and rotational forces of the motor Convertible: Can be reconfigured from left to right version Ridder Article No.: 550508 (L) / 550509 (R) The Guide unit for tube motors RB120E+ L is a robust and convertible motor guide for Ridder RB120E+ motors. It ensures stable movement in vertical guide rails and can be easily switched between left and right configurations.

Application: Drive unit for ventilation and screen systems in greenhouses or barns Voltage: 400–450 V, 3~, 50 Hz Speed: 5 rpm Limit switch: Integrated linear limit switch system with a 97-turn operating range Features: Self-locking worm gear for secure shaft position at standstill Quiet operation due to optimized gear combinations Maintenance-free and compact design Optional RPU PositioningUnit or potentiometer feedback Graphite-grey powder coating Ridder Article No.: 502020 The RW45-5 / 400–450 V is a powerful and compact gear motor for greenhouse ventilation and shading systems. It features a self-locking worm gear, precise limit switch control, and optional feedback integration for climate automation. Built for durability and quiet operation.

Application: Maintenance-free gear motor for ventilation, screen, and lifting systems in greenhouses and livestock buildings Material: Robust construction with high protection class IP55 Voltage: 400–450 V, 3-phase Speed: 5 revolutions per minute Limit Switch: Patented linear limit switch system with high switching accuracy Temperature Range: Suitable for ambient temperatures from 0–60 °C Feature: Low-noise operation through optimized gear and worm drive; output shaft compatible with Tower Roller Plus and telescopic systems Ridder Item No.: 532259 The Ridder RW245-37/400-450 Grease Drive is a maintenance-free gear motor designed for ventilation, screen, and lifting systems in greenhouses and livestock facilities. Its robust IP55-rated housing ensures reliable protection against dust and water, even in demanding environments. Operating at 400–450 V and a constant speed of 5 revolutions per minute, the RW245-37 enables precise and dependable motion control. The patented linear limit switch system ensures accurate shaft positioning and high switching precision. The optimized gear and worm drive combination allows for quiet operation and secure self-locking when stationary. The output shaft is specifically designed for direct compatibility with Tower Roller Plus and telescopic systems, eliminating the need for mechanical adaptations. Optionally, the drive position can be transmitted to a climate computer via the RPU PositioningUnit or a potentiometer kit.